Propane is a liquefied petroleum gas and aromatic hydrocarbon that may be utilized as a gaseous fuel. Propane's best known hydrocarbon neighbors are methane (natural gas) and butane (disposable cigarette lighters). Unlike methane vapor that is lighter than air, propane vapor is heavier than air. Unlike liquid butane that will not vaporize at temperatures less than 32 degrees Fahrenheit, liquid propane will vaporize at any temperature above -44 degrees Fahrenheit. A gallon of liquid propane weighs 4.24 pounds and contains 91,650 BTU's. Propane, and all other hydrocarbon based fuels, must be kept away from open flame(s) and ignition sources. Propane must also be handled with care, transported properly, and stored safely.

The majority of propane consumed in the United States is produced in the United States and Canada. Liquid propane reaches your home via a network of pipelines, rail cars and delivery trucks. Your Mountain View propane system has been installed in accordance with NFPA Pamphlet #54, NFPA Pamphlet #58, and any applicable state or local codes.

Propane is sold as a liquid (U.S. gallon), by the pound, or as a vapor by the cubic foot. Your residential appliances consume propane in its vapor form. Propane vapor reaches your appliances through your propane distribution system. When your Mountain View propane system was installed it was determined to be 100% safe and leak free. Absolutely no alterations or modifications should be made to your propane system by anyone other than Mountain View Propane authorized personnel.

The slightest modification or alteration to your propane system by unauthorized personnel may cause a potentially dangerous or life-threatening situation.

Any propane system may develop faults that will allow propane vapor to escape. Propane vapor most often evidences itself via its distinctive unpleasant odor. The presence of propane's distinctive odor indicates that propane vapor is likely to be present and a potentially dangerous situation may exist. Should this situation ever present itself, extinguish all open flames and immediately leave the area where the odor is present. Do not touch any electrical switches or appliances. Go directly to your propane system's storage vessel, open the tank hood and close the vapor service valve. Under no circumstance should the vapor service valve be left open or be re-opened. Proceed immediately to the nearest off premise telephone and contact us for further instructions.

In rare instances, certain individuals may be unable to detect propane's odor. In these situations, an electronic leak detector should be utilized.

Propane vapor is heavier than air. As such, in the event of an unintended release of propane vapor, the vapor will migrate to the lowest point. In example, your basement or crawl space.

Propane must be handled with caution. In the unlikely event that a propane leak should occur, take the following steps:

Carbon monoxide is a colorless and odorless gas that cannot be detected through sense of smell or taste. Exposure to carbon monoxide may cause you to experience any or all of these symptoms:

If any of these symptoms develop, move outdoors immediately. Have your propane system and attached appliances inspected and repaired before you return to the building or area where carbon monoxide is suspected.

We do provide two varieties of scientific, quantitative, carbon monoxide testing to our customers. A nominal fee applies to both methods.

HOW TO PREVENT CARBON MONOXIDE POISONING

Your safety, and the safe use of your propane gas system are of our primary concern. Please contact us if you ever have any questions about the operation, or maintenance of your propane gas system and appliances.

When produced, propane is colorless and odorless. For safety and detection purposes, a chemical odorant (ethyl mercaptan) is added to propane. The presence of the odorant alerts you of a potential propane gas leak.

Under certain circumstances, the odorant in propane gas may oxidize and lose it's distinctive odor. This odor fade can occur in new steel containers when first placed into service and in older steel containers that have been left open to the atmosphere. Not all people are able to detect the presence of the propane's odorant. Physical conditions such as competing odors, colds, flus, allergies, or smoking may diminish a person's ability to detect the odorant.

If you think that you cannot detect the presence of the odorant, or if you have an impaired sense of smell, please contact us. A service technician will verify the presence or absence of odorant present in your system. If you suffer from and impaired sense of smell, consider the installation of an electronic gas detector.

Only AGA approved appliances that are properly installed and adjusted may be connected to your gas system. A properly adjusted gas appliance produces carbon dioxide and water vapor as by-products of combustion. Improperly adjusted appliances are dangerous and can produce, among other things, carbon monoxide.

Never attempt a "do it yourself" repair on any gas appliance. Only qualified technicians should attempt the installation or repair of gas appliances. If you are experiencing a problem with any of your gas appliances please contact us. One of our technicians will correct the problem.

YOUR REGULATORS AND DISTRIBUTION SYSTEM

As the ambient temperature rises, propane vapor pressure rises. When the ambient temperature drops, propane vapor pressure drops. To alleviate this temperature induced fluctuation of vapor pressure, your first stage regulator and second stage regulator (or if utilized, integral two-stage regulator) maintain a constant service pressure to your appliances.

GENERAL CONTAINER INFORMATION

Propane is sold and stored in portable DOT containers or fixed placement ASME containers. When a container is filled to its proper liquid level it will be approximately 80 percent full. The remaining 20 percent of the container's volume contains propane vapor. This is the propane vapor consumed by your appliances.

The vapor space in the container also provides room for the expansion of liquid propane. Liquid propane has a moderately high coefficient of expansion and accordingly, expands greatly when subjected to temperature increases.

If a container is filled beyond it maximum permitted liquid filling density, a situation may develop in which there will not be enough space available to accommodate the liquid propane's expansion. When an overfilled container is exposed to any temperature increase, the following hazardous conditions may occur:

When transporting your propane gas container, or storing it for future use, a few simple precautions must be followed:

Only properly trained technicians may engage in container refilling.

New containers must be properly purged by a qualified technician prior to their initial filling. This insures that your appliances will operate properly. The presence of oxygen in an improperly purged container can diminish the containers odorant level and cause excessive pressures. Once a container has been properly purged, the vapor service valve must remain closed, except when in use.

Containers are filled by weight or fixed liquid level gauge to prevent overfilling. It is imperative that your container be filled by a qualified technician.

The exterior of your container should be protected with light-colored, heat-reflective paint. This will reduce pressure increases as ambient temperatures rise. A proper exterior coating will protect against rust and corrosion. Aluminum containers do not require painting.

When taking advantage of Mountain View rental tank service, all container maintenance is provided free of charge.

High Pressure Regulator

Reduces tank pressure from 250 psi to 10 psi, which is the pressure needed to supply gas systems with higher pressure from the tank to the second stage regulator, which typically enters the structure. Regulator is typically located at tank.

2nd Stage Regulator

Reduces line pressure from 10 psi to 11 inches of water column. Regulator is typically located at the house.

Twin Stage Regulator

Reduces tank pressure from 250 psi to 11 inches of water column. Regulator is typically located at the tank.

2 PSI Regulator

Reduces service line pressure from 10 psi to 2 psi going into the building. Additional appliance regulators are needed inside near appliances to reduce operating pressure to 11 inches of water column. Regulator is typically located on outside of the building.

The amount of gas in the tank is found by multiplying the % by the capacity of the tank. For example: 22% in a 250 gallon tank equals 55 gallons (.22 X 250 = 55 gallons)

This reading shows a psi reading from 0-300 psi and has very little to do with capacity remaining in the tank. Do not use this reading when reporting tank level to your provider.

Percent reading can be calculated by dividing reading by tank capacity. For example: 55 gallons in a 250 gallon tank equals 22% (55 / 250 = 22%)

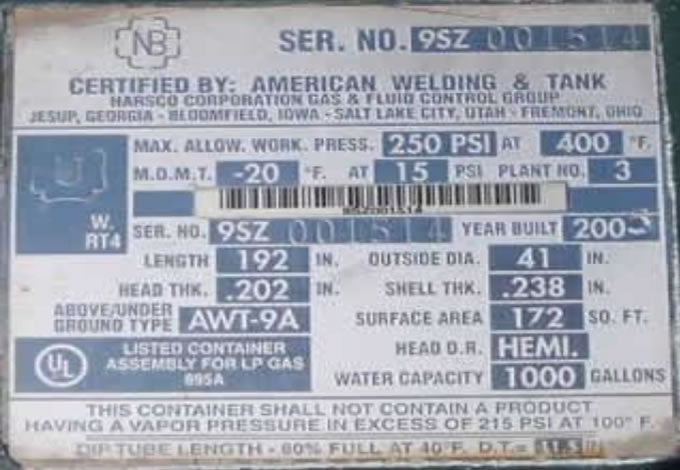

Locating the water capacity on the bottom right of this picture will give you the overall size of the container. The allowable working pressure at top center should always be 250 psi for propane tanks. Some older propane tanks have allowable working pressure of 200 psi and should no longer be filled. Manufacture, container serial number, year built and container specs are also listed on this data plate. If you are able to locate a sticker/tag identifying a propane gas company, this indicates that the tank is likely owned by that company. You will need to contact the company to determine a course of action for either obtaining service from them or having them remove the tank. If a propane tank is leased from a propane gas company, that company is the ONLY propane provider that may service that tank. If you determine that you own the tank, the owner can then contact any propane gas company they choose for service.

If you need Propane, click below to order.

CONTACT US

10902 Highway 4

Jemez Pueblo, NM 87024

Mailing Address

P.O. Box 221

Jemez Pueblo, NM 87024

We proudly service the following areas in Jemez Pueblo NM, Albuquerque NM, Algodones NM, Bernalillo NM, Cuba NM, Jemez Springs NM, Los Alamos NM, Pena Blanca NM, Placitas NM, Rio Rancho NM, Santa Fe NM, San Ysidro NM, and surrounding areas.